PA6, whose chemical name is polycaprolactam, is also known as nylon 6. It is an important member in the field of polymer materials. With its unique properties, it is widely used in both industry and daily life.

PA6 is formed by the ring - opening polymerization of caprolactam monomers. Under the action of catalysts such as sodium hydroxide and water, caprolactam is heated to 250 - 270℃, and the lactam bond undergoes ring - opening. The monomers are gradually linked to form high - molecular - weight polycaprolactam. In industry, a continuous polymerization process is often adopted. The raw materials and catalysts are continuously added to the reactor in proportion, and after reaction and post - treatment, PA6 products are obtained.

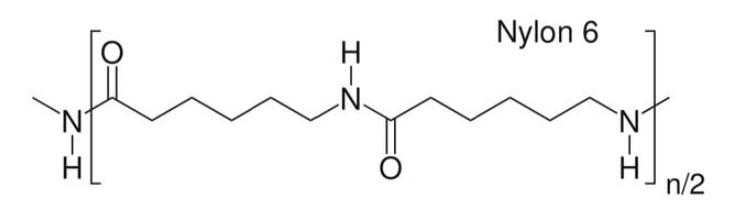

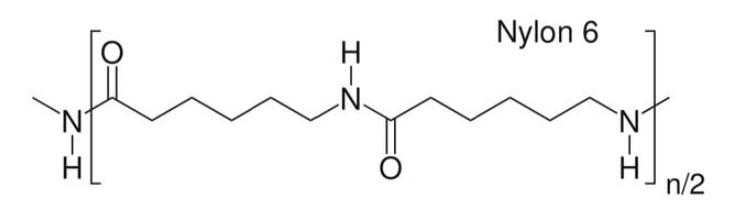

The main chain of the PA6 molecule contains repeating amide bonds (-CO-NH-) and methylene segments (-CH?-). The amide bonds have strong polarity, which promotes the formation of hydrogen bonds between molecules; the methylene segments endow the molecules with flexibility.

PA6 is a semi - crystalline polymer with a crystallinity of 30% - 50%. Its crystalline structure gives it high strength, hardness, and wear resistance.

Chip - grade PA6:

It is a chip product from conventional polymerization, used in injection - molded products, fibers, etc., and has a wide range of applications.

Direct - spinning - grade PA6:

The spinning melt is directly made during polymerization, eliminating the re - melting process of chips and reducing costs. It is mainly used for producing PA6 fibers.

Reinforced PA6:

Reinforcing materials such as glass fibers and carbon fibers are added to improve strength, rigidity, and heat resistance. For example, 30% glass - fiber - reinforced PA6 can increase the tensile strength by 2 - 3 times, and it is used for structural parts in automobiles and machinery.

Flame - retardant PA6:

Bromine - based and phosphorus - based flame retardants are added to endow PA6 with flame - retardant properties. It is used for the outer shells of electronic and electrical appliances, and the cladding of wires and cables.

Toughened PA6:

Rubber - like toughening agents are added to improve toughness and impact resistance. It is used for sports goods, children's toys, etc.

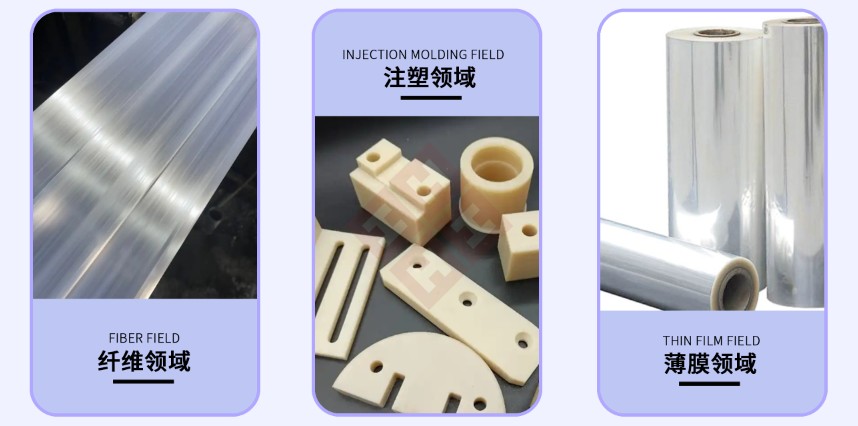

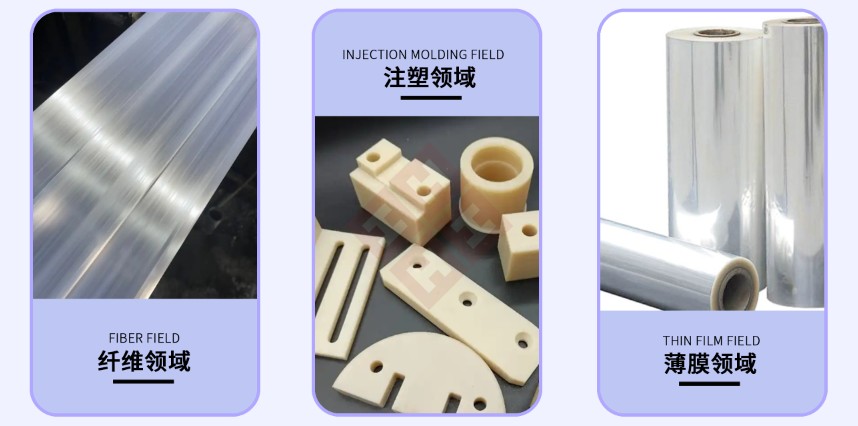

PA6 fibers have high strength, wear resistance, and good moisture absorption. They are used in clothing fabrics, such as sportswear; in industry, they are used to make tire cords, ropes, fishing nets, etc.

PA6 has excellent molding and processing properties. In the automotive industry, it is used for components around the engine. In the field of electronics and electrical appliances, it is used for outer shells and connectors. In the daily necessities field, it is used for combs, clothes hangers, etc.

PA6 films can block oxygen and water vapor. They are used for food packaging to extend the shelf life and for the moisture - proof and anti - oxidation packaging of electronic components in the electronics industry.

With its diverse properties, PA6 materials play an important role in various fields. With the development of technology, it will continue to expand its applications, continuously empowering our lives and industrial development.